- Have any questions?

- (+212) 0537-794-299

- (+212) 0537-282-805

- info@expertmedicalholding.com

C-FIT 3D

BROCHURE TIN

27 octobre 2020

CORTINA HIP STEM

27 octobre 2020

C-FIT 3D

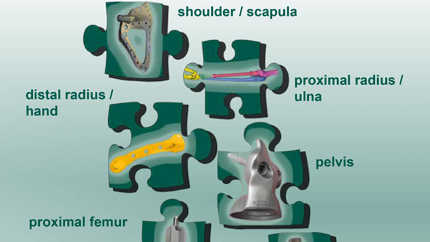

The demand for custom made implant components increases continuously in revision and tumour endoprosthetics. Complicated bone defects after single or multiple revision or large tumour resections often do not tolerate treatment with standard implant components. implantcast GmbH is able to generate a 3D model of the bone or joint to be reconstructed from high-resolution MRI or CT data. With dedicated software it is possible to segment the body-section radiographs in transversal, saggital and frontal plane. Thus relevant bones can be reproduced and separated from remaining tissue. Finally it is exported as a 3D model, which is the basis for constructive implementation of the custom made implant component. That procedure allows for exact adaptation of the implant to the individual anatomical situation of the patient. For manufacturing custom made implant components implantcast GmbH uses the additive manufacturing technology to a great extent due to its many advantages. In the following the different case studies should give you an overview of the possibilities of custom made prosthetics and patient specific instrumentation.